Gamechanger – Using innovative XR in food safety training

Originally published in Food in Canada, January 6, 2023

Conestoga College’s Food Research and Innovation Lab has been prototyping an innovative new training strategy using extended reality (XR) simulations for employees in Ontario provincially registered meat processing facilities. Developed in collaboration with industry partner VG Meats and the college’s Virtual and Augmented Reality Lab, the learning simulations provided an engaging and informative training and refresher for the plant employees. Employees explored modules on handwashing, sanitation, and good manufacturing practices, with the prototype demonstrating the potential to make a profound and positive change on how food manufacturing employees are trained.

The research team from the college took photoreal images at the plant and created short games for the employees to practice some of the crucial processes they perform in their jobs. Unlike virtual reality (VR), headsets were not required for this immersive experience. Employees were given Chromebooks and were asked to play the simulation and respond to questions about what the experience was like for them. Results were promising, and the success of the prototype suggests this project may have important implications for training in the food manufacturing sector.

Playing a game that realistically portrayed their working environment was helpful for participants, and reinforced earlier training they had done. One of the strategies employees spontaneously adapted was to sit with one another and go through the simulation together, while discussing the best options on the knowledge checks built into the game. Participants were given immediate feedback throughout the game confirming their understanding. Employees with stronger language skills supported newcomers with developing English literacy.

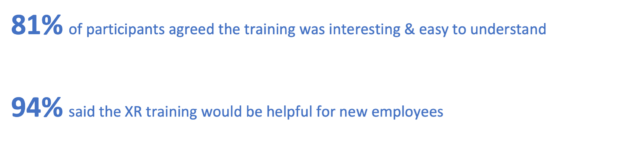

Although not intended to replace instructor-led training, this innovative learning experience offers employees the opportunity to practice, remember and rehearse their processes in a familiar environment which reinforces and strengthens learning. Research using immersive simulations in other industries has shown dramatic increases in knowledge retention compared to traditional training methods. Considerations to support the success of implementing XR training include: a fast Wi-Fi connection, the availability of headphones, and newer laptops that can effectively process image-intensive games. The initial success of this OMAFRA (Ontario Ministry of Agriculture, Food and Rural Affairs)- funded project suggests that XR training in food processing and manufacturing has the potential to become more innovative, engaging, and effective.